Das innovative und CE-zertifizierte Dämmsystem für vielseitige Anwendungsbereiche.

ThermoWhite® ist die mineralisch, gebundene Dämmschüttung für Boden, Flachdach, Steildach, Dachboden, Gewölbe und Poolhinterfüllung.

Wohlfühlen in den eigenen vier Wänden und ein angenehmes Raumklima schaffen. Sich im Winter vor Kälte schützen und im Sommer vor Hitze. Das alles hängt unmittelbar mit der Beschaffenheit der verwendeten Baumaterialien und der Wärmedämmung zusammen.

Ob Neubau, Sanierung, Poolhinterfüllung oder Dachbodendämmungen – mit ThermoWhite® treffen Sie die richtige Wahl.

Das ThermoWhite®-System ist nachhaltig und ausgezeichnet mit dem ENERGY GLOBE AWARD (Ausgezeichnet 2019)

Thema EPS Recycling: Bei der ThermoWhite®-Produktion wird recyceltes Styropor (EPS) verwendet. Dies entspricht unserem Bedürfnis, umweltgerechte Prozesse zu etablieren.

RECYCLING STYROPOR DER UMWELT ZU LIEBE.

Die Thermowhite Zentrale in Spital am Pyhrn, Oberösterreich, setzt auf 100 Prozent erneuerbare Energie. Die Firmenflotte wird regelmäßig mit neuen Elektro-Fahrzeugen ausgestattet.

ThermoWhite® Poolhinterfüllungen

Die perfekte Lösung für ihren Pool. Hocheffizient und energiesparend im Einsatz. Wärmedämmend und schützend. Spezielle und schonende Einbringung.

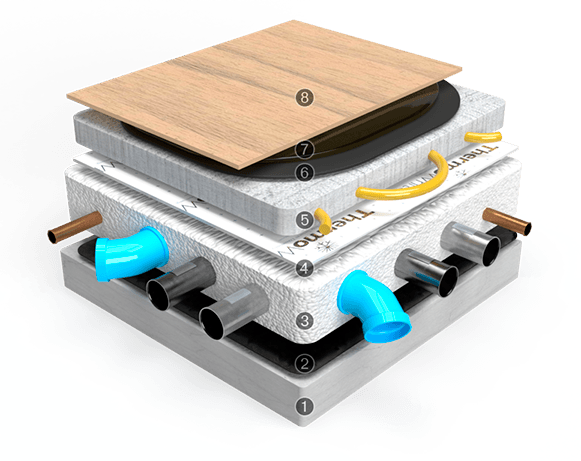

- Bodenplatte

- Bauwerksabdichtung

- ThermoWhite-Dämmschüttung

- Folie-Dampfbremse

- Estrich

- Grundierung

- Kleber

- Boden

Die Vorteile

- Trittschallverminderung bis 32 dB

- λ-Werte bis 0,0381 WmK

- CE-Kennzeichnung unserer Produkte

- Verkehrslasten bis 20kN/m²

- 100% HBCD-frei

Videos, Folder, Datenblätter, etc.

Detailierte Informationen zum ThermoWhite® Dämm-System und unseren Baustoff-Produkten finden sie hier zum herunterladen. Auch Videos zur Verarbeitung, Prüfberichte und Unterlagen für Architekten sind dort zu finden.